Aviation is a striking example of a sector that is difficult to decarbonise, because batteries, hydrogen and hybrid combinations are limited by their low energy density, whilst bio-fuel is limited by the fuel vs. food and flora trilemma. The KEROGREEN project offers an innovative third way by producing green kerosene, synthesised from air and water, powered by renewable electricity (wind, waves, solar) and recapturing the carbon emitted from the atmosphere, creating a closed carbon fuel cycle consistent with the circular economy principle.

An important advantage of green kerosene as an aviation fuel is that existing infrastructure for storage, transport, filling of aircraft and, more importantly, jet engine technology can be kept unchanged. Furthermore, synthetic green kerosene, emits no sulphur and less soot, whilst NOx emission are minimised, hence emissions also meet ever tighter ait pollution standards. The KEROGREEN technology is modular, scalable and well suited to small-scale distributed production plants sited in remote areas, for example an off-shore wind turbine park or a desert solar farm.

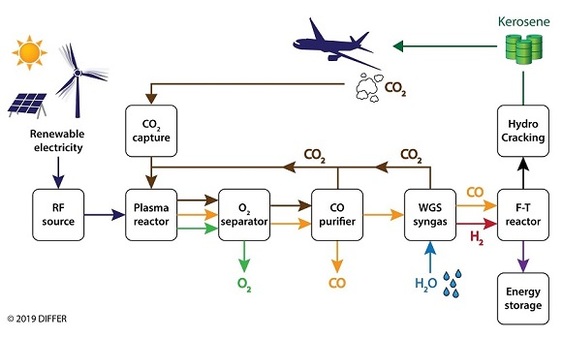

The KEROGREEN conversion route is based on plasma driven dissociation of air captured CO2, solid oxide membrane oxygen separation of and Fischer-Tropsch (F-T) kerosene synthesis. Synergy between plasma activated species and novel perovskite electrodes of the oxygen separator raise CO productivity and energy efficiency. CO2 emitted upon fuel usage is recirculated as feedstock to the process by direct air capture. The technology relies on inexpensive existing infrastructure for storage, transport and distribution.